🛠 PVC pipe (¾-inch or 1-inch, depending on knife tang size)

🔥 Heat gun or blowtorch

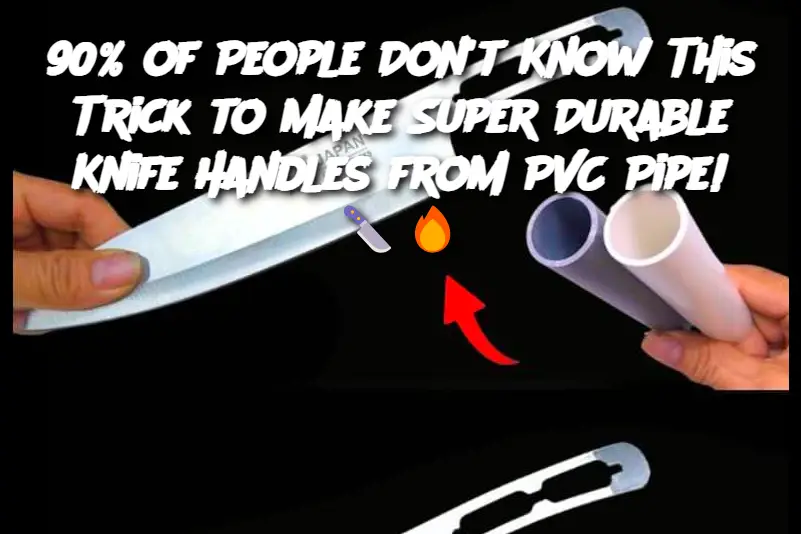

🔪 Knife tang (blade without a handle)

🧤 Heat-resistant gloves (for safety)

🗜 Clamps or pliers

🛢 Sandpaper or file (for smoothing edges)

🎨 Paint or grip tape (optional for finishing touches)

Step-by-Step Guide to Making a PVC Knife Handle

📌 1. Measure & Cut the PVC Pipe

- Cut a section of PVC pipe about 6 inches long (adjust based on knife size).

- Ensure the diameter is wide enough to fit over the knife tang.

📌 2. Heat the PVC Pipe 🔥

- Use a heat gun or blowtorch to soften the PVC.

- Rotate the pipe evenly to avoid burning or melting holes.

📌 3. Insert & Shape the Handle

- Once the PVC is soft and pliable, quickly slide the knife tang inside.

- Use gloved hands or clamps to mold the PVC tightly around the tang for a secure fit.

- Press the PVC into a comfortable ergonomic shape while it’s still warm.

📌 4. Cool & Harden

- Once shaped, run the handle under cold water to solidify it quickly.

- Check for a tight grip on the tang—it should be firm and not move.

📌 5. Sand & Customize

- Use sandpaper or a file to smooth rough edges.

- (Optional) Add paint, grip tape, or a textured surface for extra grip.

📌 6. Secure the Handle (Optional)

- For extra durability, drill small securing holes and add pins or epoxy glue.